On September 2009 YUZHMASH installed and now uses actively the fluorescent control GS-1206-4.4. This line is designed for the detection of surface discontinuities, defects by the method of capillary flaw detection (OST 190282-79 Lum 1-OV, nondestructive testing).

Ultra-high sensitivity (corresponding to the 1st conventional level of OST 190 282, GOST 18442, or the 4th level of foreign n standards) reveals a defect (crack) with a minimum value of opening – 0.5 microns. The limiting sensitivity can be achieved when the roughness grade no lower than fifth.

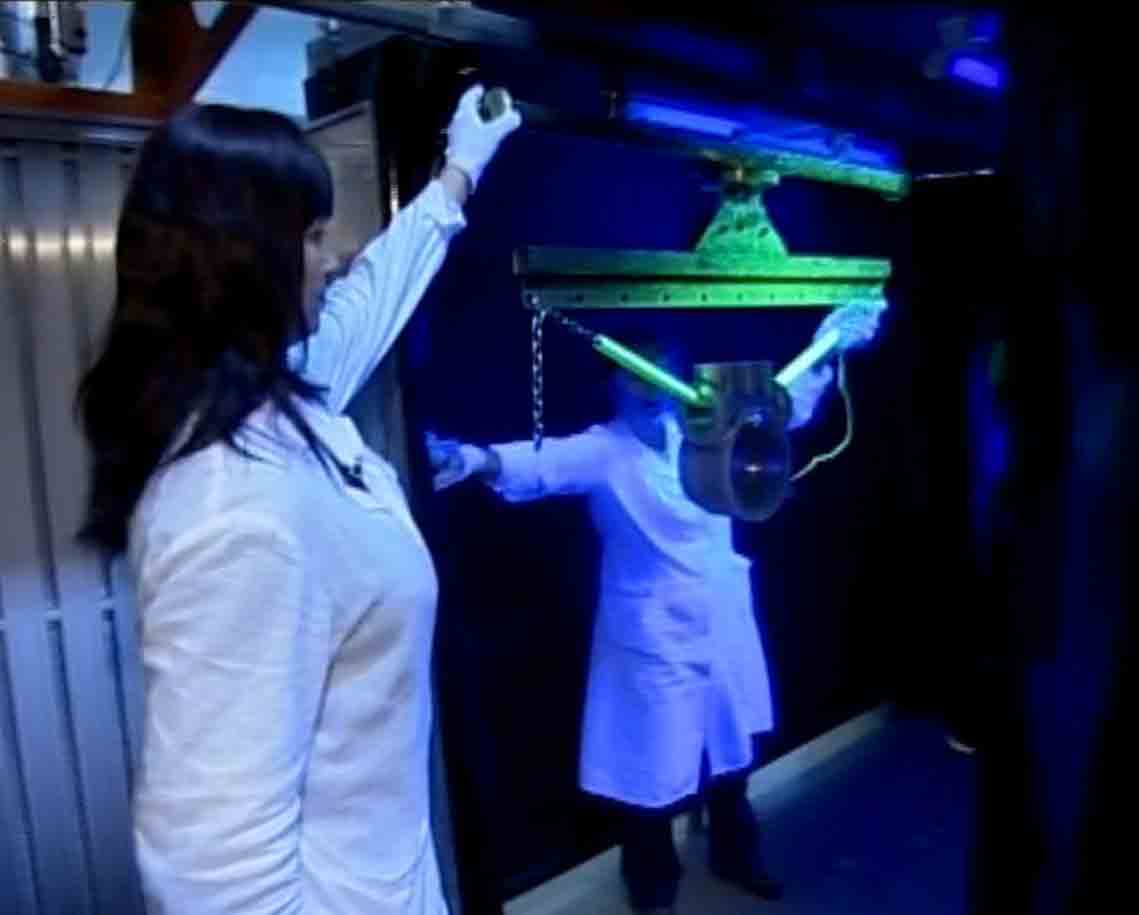

The line has a manual control system equipped with a circulating (monorail) suspension-type conveyor. Bracket for moving parts can withstand loads of up to 150 kg.

Availability of special UV spray equipment and a darkened inspection cabin allows using specifically contrasting fluorescent penetrates as consumables.

The fluorescent control line has two drying chamber, each of them is configured as a continuous air flow (t = 70-90 º C). The size of the drying chamber allows control of large details.

The OST 190282-79 Lum 1-OV line provides an opportunity for control the base metal and welded joints, nodes at different stages of manufacturing, in service, in the repair of items of aircraft, rocket and space technology, as well as in other industries. Capillary method allows testing objects of any shape, of different sizes, made of ferrous and nonferrous metals and alloys, plastics, glass, ceramics and other hard non-ferrous materials.

The complete check out of details takes about 2 hours.

Carbon filters ensure environmental purity of the line.

Upon test completion experts make a condition inspection report of the detail.

The company’s employees passed specialized training to work on the line, and also have certificates of non-destructive control issued by the Notified Authority for certification of personnel in the field of non-destructive control. Personnel certification on luminescent control takes place every three years.