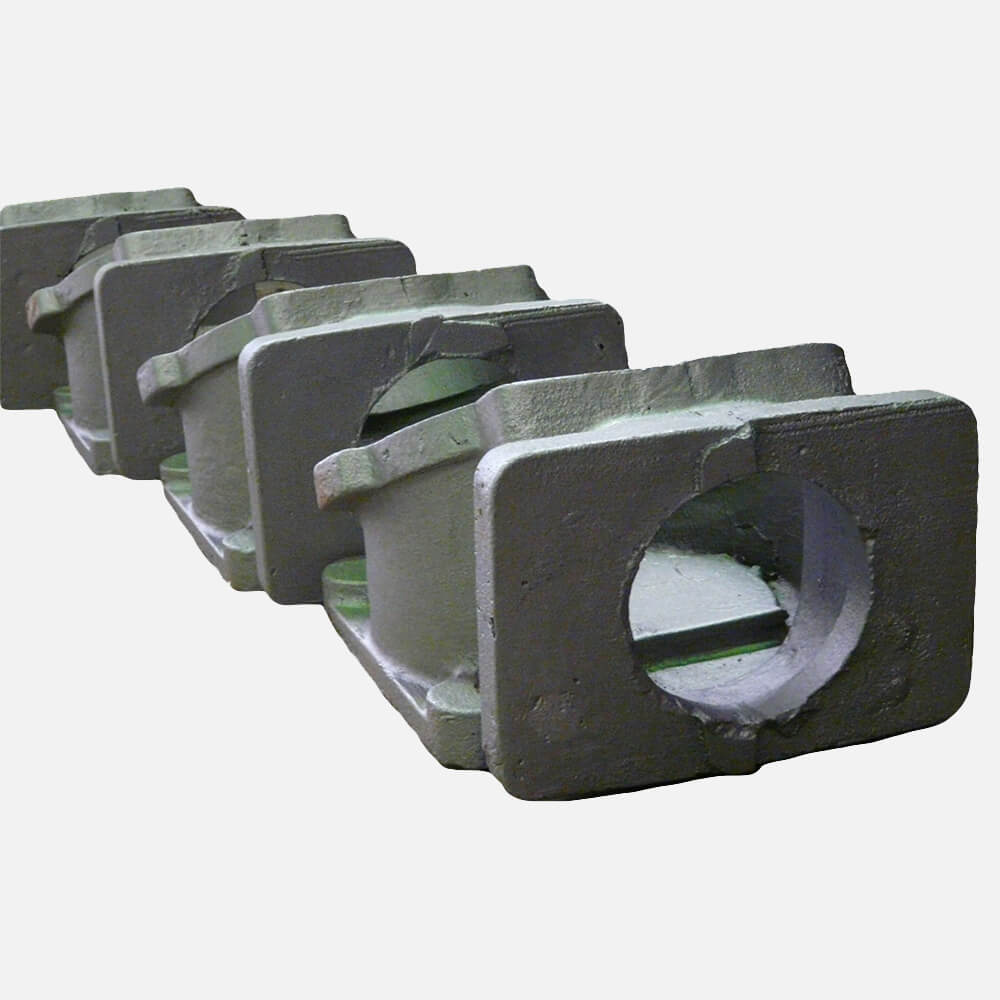

Description

YUZHMASH produces both in lots and single item ferrous castings for enterprises of different sectors of national economy.

Methods of producing a cast parts:

- sand molding

- chill casting

- shell molding

The accuracy of manufactured parts:

- sand molding with a tolerance of ±3%

- shell molding with a tolerance of ±1 -1,5%

Material:

- carbon steel 30L, 35L, 40L, 45L types, as well as heat-resistant steels

- gray iron grades SCH10, SCH20, GCH25

Quality management system of the product complies with the national standards, steel in accordance to GOST 977-88 state standard specification, gray iron accordance to GOST 1412-85.

Casting manufacturing period:

- according to the available patterns and mold – 15 – 30 days

- without patterns and mold – 60 days

The company is constantly expanding the range of products. Customer only need to submit drafts, according to which will be designed and constructed a model prototype and produced an experimental batch of castings.